Even if you use the same logistics company, delivery fees may frequently differ depending on the branch or office used. In such a case, logistics costs can be reduced by consolidating the contractor's contacts and shippers, thereby increasing the size of each delivery transaction, and receiving quantity discounts. Furthermore, arranging joint delivery for common destinations will lead to a significant reduction in delivery costs. Fuji Logitech proposes such projects for integrating delivery operations of clients in various industries.

Even if you use the same logistics company, delivery fees may frequently differ depending on the branch or office used. In such a case, logistics costs can be reduced by consolidating the contractor's contacts and shippers, thereby increasing the size of each delivery transaction, and receiving quantity discounts. Furthermore, arranging joint delivery for common destinations will lead to a significant reduction in delivery costs. Fuji Logitech proposes such projects for integrating delivery operations of clients in various industries.

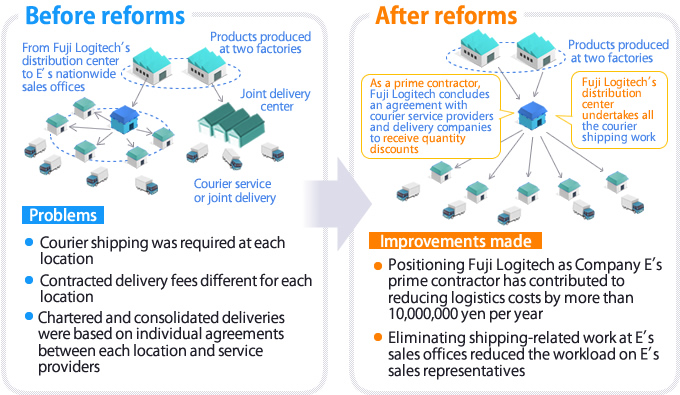

Food product manufacturer E had delivered its products produced at two factories in the Chubu area to retailers' comprehensive distribution centers and stores using either of the following logistics processes: (1) Fuji Logitech's distribution center → E's more than a dozen sales offices nationwide → door-to-door delivery using a courier service or E's sales representative; or (2) joint delivery center → courier service or joint delivery. Courier shipping-related work was required at each location including factories, Fuji Logitech's distribution center, the joint delivery center, and E's sales offices, with different contracted fees for each location. In addition, chartered and consolidated deliveries between factories and sales offices and joint delivery centers were based on individual agreements between each location and service providers.

In our reform project, first, we positioned ourselves as a prime contractor for delivery operations to receive quantity discounts by concluding an agreement with courier service providers as well as consolidated and chartered delivery companies. We also proposed that our distribution center undertake all the courier shipping work that had been done at E's sales offices. This would enable E's sales representatives to focus on sales activities targeting customer stores, without spending valuable time on cumbersome shipping work.

Positioning Fuji Logitech as Company E's prime contractor has contributed to reducing logistics costs by more than 10,000,000 yen per year. In addition, eliminating shipping-related work at E's sales offices has promoted the separation of sales and logistics operations, which reduced the workload on E's sales representatives. We are also planning to carry out the following activities as future steps of the project: (1) total management of E's logistics operations by Fuji Logitech; (2) order-processing service by Fuji Logitech; (3) operation of factory warehouses by Fuji Logitech; (4) consolidation of logistics sites to reduce inventory; and (5) further separation of sales and logistics operations to reduce store-supporting activities by E's sales representatives.

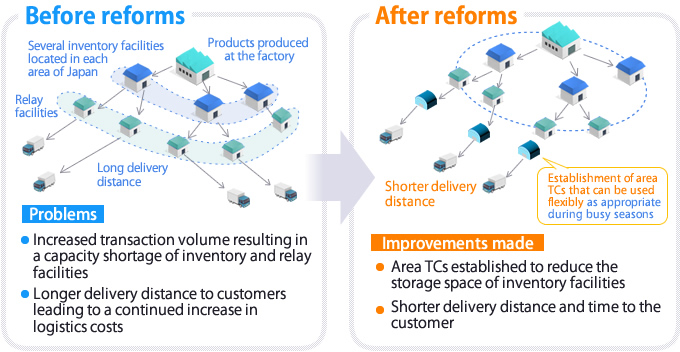

A major construction material manufacturer F had produced its products at a factory in the Chubu area, and supplied them in accordance with the following process: inventory facility (located in each area of Japan) → relay facility (without inventory) → customer. In recent years, however, the transaction volume has increased as a result of business expansion, and the capacity of inventory and relay facilities was falling short. Furthermore, as the delivery distance between inventory/relay facilities and customers increased, the logistics costs continued to rise.

First of all, in order to resolve the capacity shortage, we proposed establishing "area TCs" near the inventory and relay facilities. We defined these area TCs as a temporary logistics facility that can be used flexibly as appropriate during busy seasons. Our aim was to make the delivery distance from the area TC to customer as short as possible.

Establishing area TCs has enabled us to reduce the storage space of the inventory facility in charge of an area, and shorten the delivery distance and time to the customer. We will continue our commitment to reduce logistics costs by enabling joint delivery with different products, in addition to switching the traditional pricing system based on the number of (chartered) trucks used or distance to a new pricing system based on the number of cargoes delivered.

Contact Us

Contact Us Fuji Logitech's Strengths

Fuji Logitech's Strengths

Creating optimized logistics strategies through our "Operations Capabilities", "Analysis and Proposal Capabilities", and "System Development Capabilities"

NEO ACTION

NEO ACTION

We provide our clients with helpful information by matching vehicle demand and cargo demand information.