Fuji Logitech has provided and implemented an abundance of logistics reform projects for upstream supply chains including procurement and production. We offer many kinds of solutions such as a joint delivery project led by the procurement team (e.g. milk run), outsourcing of factory operations, inventory management of raw materials and components, as well as their supply to production lines.

Fuji Logitech has provided and implemented an abundance of logistics reform projects for upstream supply chains including procurement and production. We offer many kinds of solutions such as a joint delivery project led by the procurement team (e.g. milk run), outsourcing of factory operations, inventory management of raw materials and components, as well as their supply to production lines.

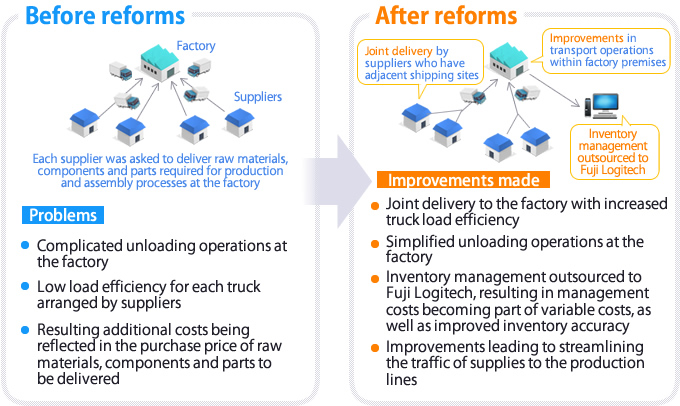

Company C had each supplier take charge of the delivery of raw materials, components and parts required for the production and assembly processes at C's factory. This, however, caused the following issues:(1) complicated unloading operations at the factory; (2) low load efficiency for each truck arranged by suppliers, and (3) the resulting additional costs being reflected in the purchase price of raw materials, components and parts to be delivered.

Given the above, we proposed a reform project that includes the following: (1) joint delivery by suppliers who have adjacent shipping sites; (2) outsourcing of inventory management of raw materials, components and parts; and (3) improvements in transport operations within factory premises.

In cooperation with supplier companies, joint delivery to the factory has been enabled with increased truck load efficiency. As we could decrease the number of delivery trucks used,unloading operations at the factory have been simplified.

In addition, as inventory management has been outsourced to Fuji Logitech, management costs have become part of variable costs, and inventory accuracy has been improved. Improvements in factory operations have led to streamlining the traffic of supplies to production lines.

Contact Us

Contact Us Fuji Logitech's Strengths

Fuji Logitech's Strengths

Creating optimized logistics strategies through our "Operations Capabilities", "Analysis and Proposal Capabilities", and "System Development Capabilities"

NEO ACTION

NEO ACTION

We provide our clients with helpful information by matching vehicle demand and cargo demand information.