In response to the latest trend of integrating production sites and changing business models, many clients have become committed to consolidating factory warehouses and regional delivery depots in recent years. To support this trend, Fuji Logitech offers 3PL services that extend all the way from planning these projects through to analyzing current logistics systems, simulating costs after making improvements and reforms, realigning different sites, operating logistics centers, and undertaking delivery operations.

In response to the latest trend of integrating production sites and changing business models, many clients have become committed to consolidating factory warehouses and regional delivery depots in recent years. To support this trend, Fuji Logitech offers 3PL services that extend all the way from planning these projects through to analyzing current logistics systems, simulating costs after making improvements and reforms, realigning different sites, operating logistics centers, and undertaking delivery operations.

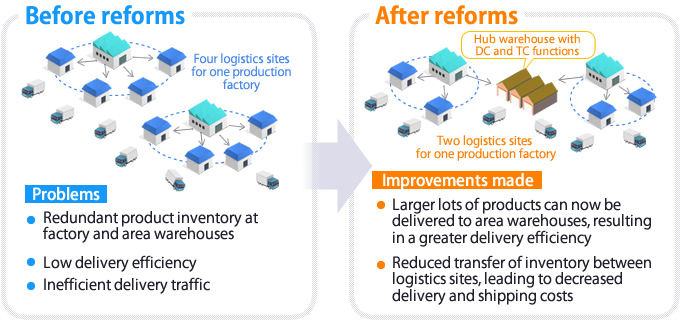

Company A had produced its products at two factories in the north Kanto region, and supplied them to end users in the Kanto-Koshin'etsu region via eight factory and area warehouses. This logistics system, however, had the following issues:(1) redundant product inventory at factory and area warehouses; (2) low delivery efficiency; and (3) inefficient delivery traffic.

We proposed a reform project that consolidates factory and area warehouses in a phased manner with the goal of reducing logistics costs by 15%.

We opened a hub warehouse equipped with DC (distribution center) and TC (transfer center) functions that manages products received from factories owned by Company A and other factories commissioned with production operations, as well as imported products, and supplies them to area warehouses. This enabled integration of factory warehouses located near factories.

Then, as part of our efforts to consolidate area warehouses, we opened a new center that covers Tokyo, Chiba, and Saitama. The traditional system that required four area warehouses has been changed into a system with two warehouses. As a result, we could reduce the total number of area warehouses from eight to four, and integrate factory warehouses into a hub warehouse. This has provided the following benefits to Company A:(1) larger lots of products can now be delivered to area warehouses, resulting in a greater delivery efficiency; and (2) reduced transfer of inventory among logistics sites, leading to decreased delivery and shipping costs.

We are now planning to start another project to streamline trunk transport nationwide, including six Tohoku prefectures and West Japan, without being limited to the Kanto-Koshin'etsu region. We will continue to provide a wide array of logistics solutions to achieve total optimization of Company A's supply chain in Japan

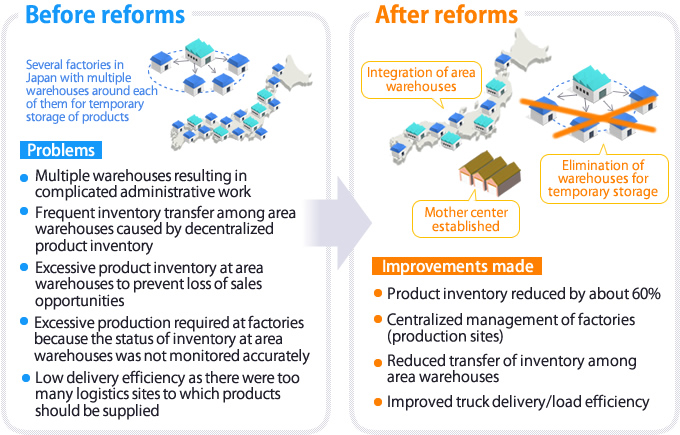

Company B had several factories in Japan, as well as multiple warehouses around each factory for temporary storage of products. In addition, an area warehouse had been sited in each block from Hokkaido to Kyushu as part of its logistics process for storing product inventory.

This process, however, had the following issues:(1) multiple warehouses resulting in complicated administrative work; (2) frequent inventory transfer among area warehouses caused by decentralized product inventory; (3) excessive product inventory at area warehouses to prevent loss of sales opportunities; (4) excessive production required at factories because the status of inventory at area warehouses was not monitored accurately; and (5) low delivery efficiency (e.g. between factory and area warehouse) as there were too many logistics sites to which products should be supplied.

We proposed a reform project to eliminate warehouses for temporary storage, establish a mother center, and promote integration of area warehouses in a phased manner.

We spent two years carrying out the following reform activities: (1) establishing a mother center next to each factory, and eliminating existing warehouses for temporary storage; (2) reducing the number of area warehouses in Japan from nine to four; (3) if a product is out of stock at an area warehouse, the product is directly sent from the mother center to the customer; and (4) allowing inventory reservation by sharing information between the mother center and supply/demand department.

As a result, we could reduce product inventory by about 60%, implement centralized management of factories (production sites), reduce transfer of inventory among area warehouses, and improve truck delivery/load efficiency.

Contact Us

Contact Us Fuji Logitech's Strengths

Fuji Logitech's Strengths

Creating optimized logistics strategies through our "Operations Capabilities", "Analysis and Proposal Capabilities", and "System Development Capabilities"

NEO ACTION

NEO ACTION

We provide our clients with helpful information by matching vehicle demand and cargo demand information.